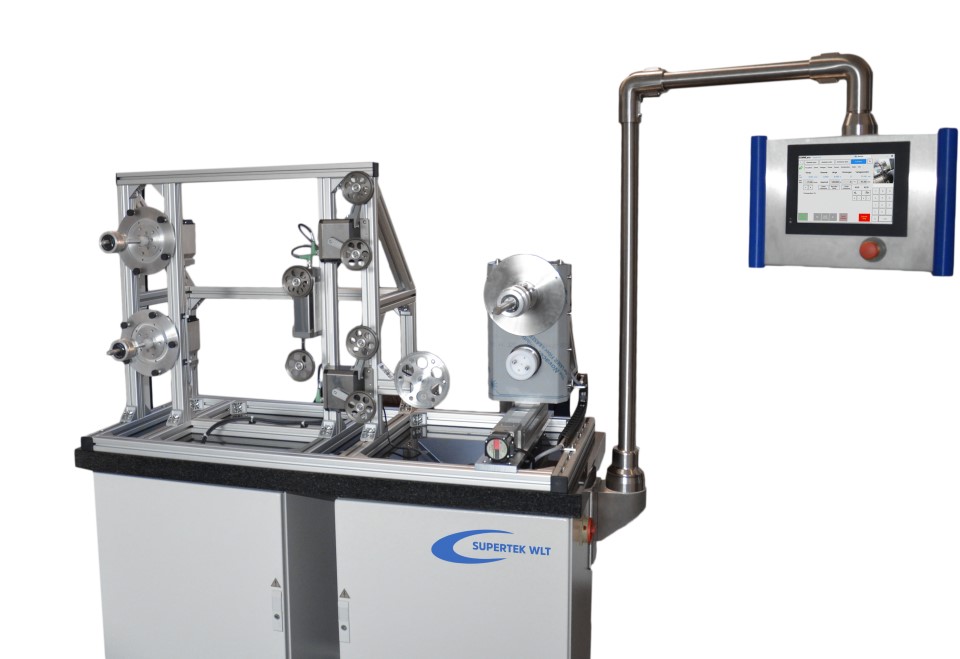

Automatic Rewinder

|

Supertek's automatic rewinders or rewinding machines consist of unwinders or pay-offs and winders or take-ups. By using modular, intelligent units (smart winder units), compact, powerful rewinding systems can be configured. Our rewinding machines are ideally suitable for precise unwinding, winding and rewinding very thin, delicate wire, flat wire, fibre glass, fibre optic cables, fibres, silk, film, solder, filament etc.

Highly accurate tensile force and tensile stress control of the unwound winding material is achieved by the modular integration of the patented electromagnetic dancer on the unwinder. Wire brakes or wire tensioners are thus a thing of the past. Winders on rewinding systems consist of fully electronic, highly accurate laying systems with which different types of winding can be performed for different spool types. So that the product to be rewound always runs straight, the winder and the unwinder can be fitted with a traversing spool drive or a multiwinder in other words. In this version a contactless overrun control always keeps the product to be unwound on the traversing unwinder in a required position so that even flat wires and other materials can be coiled up, rewound and wound in short distances. Depending on the use case and the customer's requirements, rewinding machines can be fitted with different systems, such as annealing furnaces, dyeing plants, extruders, cleaning channels, diameter measurements, lump detectors, straighteners, straightening equipment, marking systems, cutting equipment, sorting functions, memories etc.

|

|

For many wound materials, e.g. for flat wires, tapes, films or for unwinding with short distances it is important that the product is always managed on one line.

|

|

The rewinder can be operated via different HMIs using serial data communication.

Advantages of Supertek rewinders compared with traditional systems:

|

|

| Stationary or flexibly useable rewinding machine or rewinding system available in various versions. |