Automatic Payoff Module

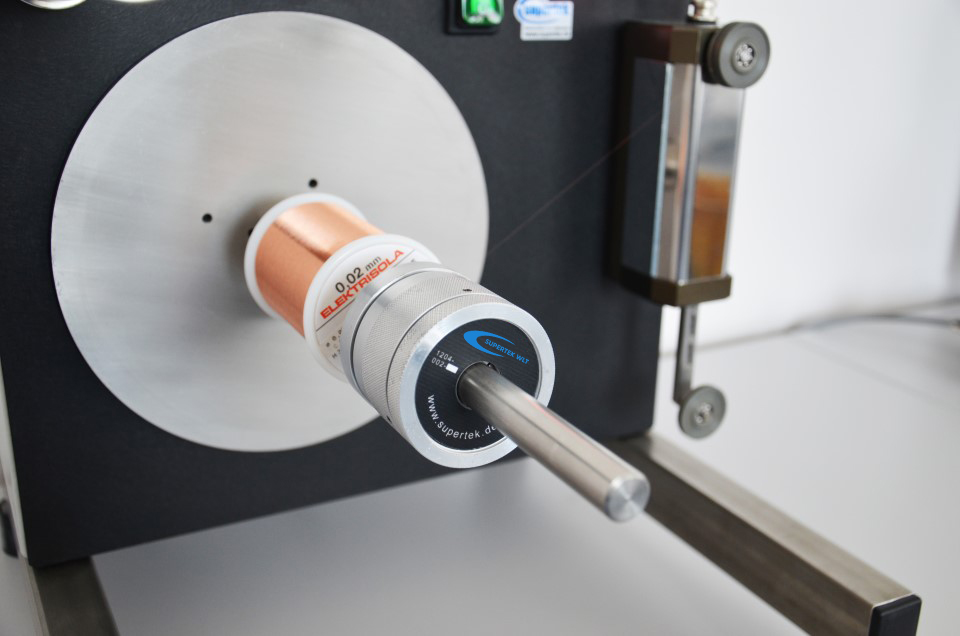

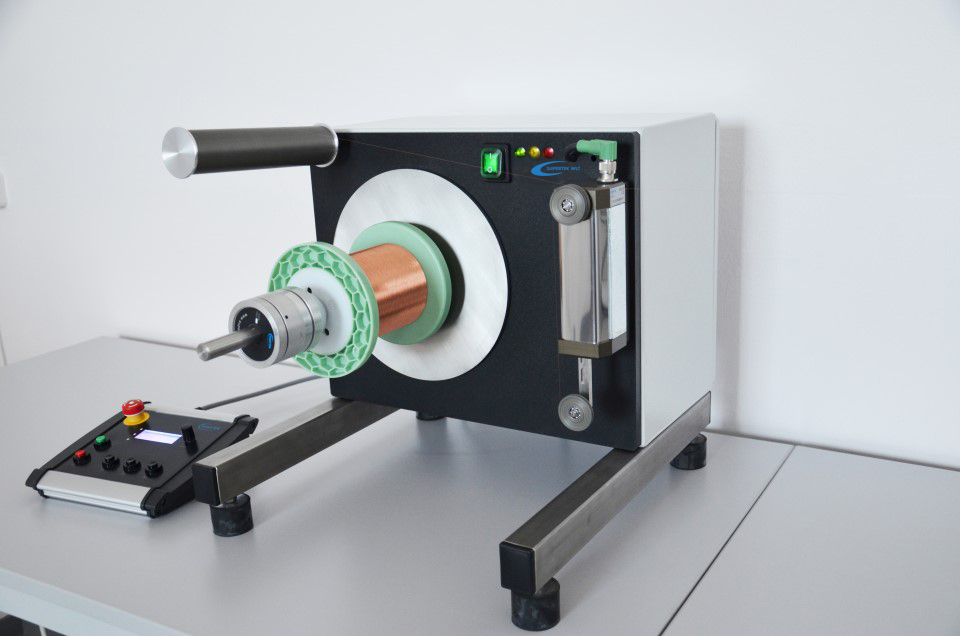

Supertek's automatic pay off winder module, uncoilers or unwinders consist of modular, intelligent units (smart winder units). They are compact, powerful and in particular they are perfectly suitable for precise uncoiling or unwinding of very thin glass fibre, fibre optic cables, fibres, finest wire, flat wire, silk, film, solder, filament, etc.

Automatic payoff winder modules are available in various versions for different coils and coil sizes with tensile force control, rpm, speed and position control.

Highly accurate tensile force and tensile stress control of the unwound winding material is achieved by the modular integration of the patented electromagnetic dancer on the payoff. Wire brakes or wire tensioners are thus a thing of the past.

For many wound materials, e.g. for flat wires, tapes, foils or for unwinding with short distances it is important that the product is always managed on one line.

Winders with additional traversing coil drives, for example the MW class of multiwinders, can move the coil in the axial direction (traversing type) as well as in a rotating movement so that the unwound material can be unwound at a fixed transfer position perpendicular to the coil.

As far as unwinders are concerned, Supertek offers a sensor-controlled overrun control that ensures that the product is always unwound at right angles to the traversing coil in a line. This avoids, amongst other things, fluctuations in tensile force even in the most delicate range and the products are less stressed.

Multiple unwinders/ uncoilers

- Consisting of a base frame and individual unwinder units.

- Special designs or component solutions available

Several unwinder units with a flexible number can be accommodated in a compact machine frame for multiple unwinders.

The unwinder is operated thanks to the serial data communication via the different HMIs. Using Supertek's operating equipment is a convenient solution for setting and monitoring the parameters. Supertek's CMC can be used for simple applications. Supertek's touch panel solutions with the PC-based SUMMI software, are suitable for more demanding applications, such as in multiple unwinders or for rewinding machines.

Obviously, operation, monitoring, formula management and data saving can also be performed by another manufacturer's PLC or HMI, such as Siemens, Beckhoff or Allen-Bradley, etc.

Advantages of Supertek unwinders compared with traditional systems:

- Intelligent, modular units

- Digital specification of parameters, e.g. tensile force

- System can be networked, digital communication

- Rpm, speed, position and tensile force control can be selected

- Highly accurate tensile force control and measurement in one unit

- Digitally adjustable tensile force with high tensile force range at high resolution in mN steps

- Increased quality, gentle, stress-free processing

- Ideally suited to the most delicate wires, fibres, glass fibre and other delicate wound materials

- Reproducible, digitally documentable tensile force control (track and traceability for consistent traceability of the line tensile force or speed)

- Fully electronic system (no pneumatics or compressed air)

- Process-dependent adjustment of the tensile force possible at any time

- Suitable for dynamic processes

- Easy to integrate into existing and new machines

- Speed measurement

- Crack detection

- Short payback period

- Increased quality

Can be uses as an unwinder, uncoiler, dispenser, outlets, shaft winder, reel, unreeler, multiple unwinder and can be used in annealing furnaces, dyeing plants, measuring devices, stranding machines, laboratory equipment, rewinding machines, winding machines etc.

Capstan

Capstans are used to isolate the tensile force and can also be used to specify the line speed or the tensile stress.

For example, if wire or solder has to be drawn out of a drum, a capstan with a connected dancer can be used as an active, tensile force-controlled capstan and thus replaces the role of a spool-driven, tensile force-controlled unwinder. Capstans are also suitable for withdrawing wires or fibres.

Supertek supplies different capstans for this with highly accurate speed or tensile force controls.